VMC850B CNC Milling machine, kikowaena mīkini kūhelu

Nā hiʻohiʻona huahana

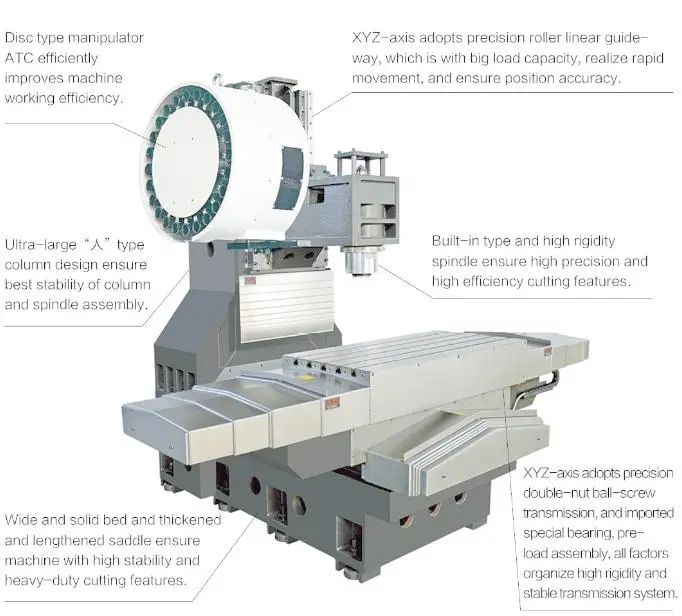

1.Overall aʻo

Hoʻolālā ʻia kēia mīkini me ka hoʻonohonoho ʻana o ka pahu kuʻekuʻe. Hoʻokomo ʻia ke kolamu ma ke kino mīkini, pahu pahu spindle ma ke kolamu e hana ana i ka neʻe Z axis, nā paheʻe noho ma ke kino mīkini e hana ana i ka neʻe Y axis, nā paheʻe Worktable ma ka noho hoʻoheheʻe ʻana i ka neʻe X axis. ʻEkolu koʻi liʻiliʻi he ala alakaʻi laina me ka wikiwiki hānai kiʻekiʻe a me ka pololei kiʻekiʻe. Hoʻohana mākou i ka hao hina hina kiʻekiʻe no ke kino mīkini, kolamu, noho, papa hana, pahu spindle me ka ʻenehana one resin a me 2 mau manawa ʻelemakule e hoʻopau i ke koʻikoʻi o loko o nā mea. Hoʻopili ʻia kēia mau ʻāpana e ka polokalamu SolidWorks, kahi e hoʻomaikaʻi nui ai i ka rigidity a me ke kūpaʻa ʻaʻole wale no kēia mau ʻāpana akā ʻo ka mīkini. Eia kekahi e kāohi i ka deformation a me ka haʻalulu i hana ʻia e ka ʻoki ʻana. Hoʻokomo ʻia nā ʻāpana koʻikoʻi mai ka inoa kaulana honua e hana i ka mīkini me ke kūpaʻa kiʻekiʻe a me ka lōʻihi. Hiki i kēia mīkini ke hoʻokō i ke kaʻina hana o ka milling, drilling, reaming, boring, reaming, tapping a hoʻohana pinepine ʻia no ka Military, mining, automotive, mold, instrumentation and other mechanical processing industry. Hiki ke hoʻohana ʻia no nā ʻano kiʻekiʻe kiʻekiʻe a me nā ʻano kaʻina hana nui. He maikaʻi ia no ka liʻiliʻi a me ka liʻiliʻi, ka hana ʻana i nā ʻano like ʻole, hiki ke hoʻokomo i ka laina hana maʻalahi.

2. ʻEkolu axes ʻōnaehana

ʻEkolu koʻi liʻiliʻi he ala alakaʻi laina a me ka hoʻolālā ākea nui no ka pololei paʻa. Hoʻopili pololei ʻia nā kaʻa o nā koʻi 3 me ka wili pōleʻa kiʻekiʻe me ka hoʻopili ʻole ʻia o ka lua. Hoʻokomo ʻia kēlā me kēia pōleʻa pōleʻa o 3 axes mai ka precision angular contacted ball screw and profession bearings matched, also we do pre-tension for the ball screws for higher accuracy and precision.The Z-axis servo motor has a automatic brake function. I ka hihia o ka mana, hiki ke hoʻopaʻa ʻia ke kaʻa kaʻa e ka pahu i mea e pale ai i ka ʻōwili ʻana, kahi hana i ka pale palekana.

3.Spindle unit

Hana ʻia ʻo Spindle e ka mea hana ʻoihana e hōʻoia i ka pololei kiʻekiʻe a me ka rigidity. Mai ka honua kaulana kiʻekiʻe precision bearing bearings, a 'ākoakoa ma ke kūlana o ka wela mau a me ka lepo ole. Ma hope o kēlā, e hana nā spindles a pau i ka hoʻāʻo ʻana i ke koena ikaika e hōʻoia i ke ola o ke ola a me ka hilinaʻi. Ua lako me ka haʻahaʻa haʻahaʻa haʻahaʻa ea pōʻaiapuni pale ʻōnaehana, puhi haʻahaʻa puʻe ea i loko o ka spindle i loko o ka hoʻokumu ʻana i ka ea pale pale e pale i ka lepo, coolant i loko. ka milo. No kēia kūlana, e hana ana ka ʻōnaewele ma lalo o ka pollution ʻole, kahi e pale ai i ka ʻāpana spindle a me ka lōʻihi o ke ola o ka spindle. ʻAʻole hiki ke hoʻololi ʻia ka wikiwiki o ka spindle i loko o ka wikiwiki o ka spindle, ka mea i hoʻomalu ʻia e ka motor i loko encode me ka hana o ka spindle orientation a me ka paʻi paʻa.

4.Tool hoʻololi'ōnaehana

ʻO 24T ka mana o ka mīkini mea hana maʻamau a ʻākoakoa ʻia ma ke kolamu ʻaoʻao. Ke hoʻololi ʻo ia i ka hāmeʻa, hoʻokele kaʻa a hoʻonoho ʻia e ka mīkini hobbing cam mīkini, ma hope o ka hōʻea ʻana o ka spindle i ke kūlana o ka hoʻololi ʻana i ka mea hana, e hoʻokō ka ATC i ka hoʻololi mea hana a hoʻouna i ka hana mea hana. ʻO ka ATC ka mīkini hobbing cam a hana i ka pre-tension a laila hiki ke kiʻekiʻe kiʻekiʻe ka hoʻololi ʻana, ʻoi aku ka maikaʻi no ka hoʻololi wikiwiki a pololei.

5.Coolant pūnaewele

Hoʻolako ʻia ka mīkini me ka pahū hoʻoluʻu hoʻoluʻu kū pololei a me ka pahu wai nui. ʻO 2m³/h ka wikiwiki o ka pauma hoʻoluʻu e hōʻoia i ka nui o ka hoʻomaʻamaʻa hou ʻana. Aia ka nozzle hoʻomaha ma ka ʻaoʻao hope o ka pahu spindle, hiki ke hana i ka mea hoʻoluʻu ea a me ka wai hoʻoluʻu no ka mea hana a me nā ʻāpana hana. Hoʻolako ʻia me ka pū ea e hoʻomaʻemaʻe i ka mīkini a me nā ʻāpana hana.

6.Pneumatic pūnaewele

Hiki i ka hui pneumatic ke kānana i nā haumia a me ka makū i loko o ke kumu kinoea e pale aku ai i ka pōʻino a me ka hoʻoneʻe ʻana o nā ʻāpana mīkini. Hoʻoponopono ʻo Solenoid valve unit i ka papahana e ka PLC e hōʻoia i nā hana o ka mea hana spindle unclamping tool, spindle center blowing, spindle clamping tool a me spindle air coolant hiki ke hana wikiwiki a pololei. I kēlā me kēia manawa paʻahana hoʻololi ʻana i ka spindle, e puhi ʻia ka ea kaomi maʻemaʻe mai ke kikowaena spindle e hoʻomaʻemaʻe i ka puka i loko o ka spindle a me ka shank mea hana no ka paʻa kiʻekiʻe o ka hui ʻana me ka spindle a me ka mea hana. E hoʻonui i ke ola spindle.

7.Machine pale

Hoʻohana mākou i ka pale pale palekana maʻamau no ka mīkini, ʻaʻole hiki ke pale wale i ka splash coolant akā ka hana palekana. Hoʻolako ʻia kēlā me kēia ala alakaʻi me ka pale pale e pale aku ai i ka mea hoʻomaha a me ka ʻāpana ʻoki i loko o ka lumi o loko a hoʻohaʻahaʻa i ka ʻaʻahu a me ka ʻino ʻana o ke ala alakaʻi a me ka pōlele.

8. Lubrication pūnaewele

Hoʻolako ʻia ke ala alakaʻi a me ka pōlele me ka ʻōnaehana lubrication waena a me ka mea hoʻokaʻawale aila volumetric i kēlā me kēia node, hiki ke hāʻawi i ka aila i nā nui a me nā manawa e hōʻoia i ka lubricated a me ka hana haʻahaʻa. E hoʻomaikaʻi ʻo ia i ka pololei a me ka lōʻihi o ke ola o ka pōlele a me ke ala alakaʻi.

9.Chip conveyor system

Hāʻawi mākou i ka mea hoʻohana maʻamau me ka hana maʻalahi. Hiki iā ʻoe ke koho i ka conveyor chip type screw a i ʻole ʻano hinge.

| 'ikamu | Unite | VMC640L | VMC640LH | VMC850L | VMC1000L |

| Papa hana | |||||

| Nui papa hana | mm | 400×900 | 400×900 | 500×1000 | 500×1200 |

| T-slot (N×W×D) | mm | 3×18×100 | 3×18×100 | 5×18×100 | 5×18×100 |

| Kaahele | |||||

| X axis hele | mm | 640 | 640 | 850 | 1000 |

| huakaʻi axis Y | mm | 400 | 400 | 500 | 500 |

| huakaʻi Z axis | mm | 400 | 500 | 600 | 600 |

| Laina mīkini | |||||

| Ka mamao mai ke kikowaena spindle a i ke kolamu mua | mm | 440 | 476 | 572 | 572 |

| Ka mamao mai ka piko o ka spindle a i ka papa hana | mm | 120-520 | 120-620 | 120-720 | 120-720 |

| Ana mīkini | |||||

| L×W×H | mm | 2200×2100×2500 | 2200×2100×2550 | 2540×2320×2780 | 3080×2320×2780 |

| kaumaha mīkini | |||||

| Max. lawe ukana o ka papa hana | kg | 350 | 350 | 500 | 600 |

| kaumaha mīkini | kg | 3900 | 4100 | 5200 | 5600 |

| Spindle | |||||

| ʻO ka ʻōniʻoniʻo puka spindle | BT40 | BT40 | BT40 | BT40 | |

| Mana milo | kw | 5.5 | 5.5 | 7.5/11 | 7.5/11 |

| Max. mākini milo | rpm | 8000/10000 | 8000/10000 | 8000/10000 | 8000/10000 |

| Hanai (kaa pololei) | |||||

| Max. wikiwiki hānai | Mm/min | 10000 | 12000 | 12000 | 12000 |

| ʻO ka māmā hānai wikiwiki (X/Y/Z) | m/min | 20/20/10 | 30/30/24 | 32/32/30 | 32/32/30 |

| pōʻalo pōʻalo (diameter + kepau) | |||||

| X axis kinipōpō pōkā | 3210 | 3212 | 4016 | 4016 | |

| Y axis kinipōpō pōkā | 3210 | 3212 | 4016 | 4016 | |

| Z axis kinipōpō pōkā | 3210 | 4012 | 4016 | 4016 | |

| Mea Paahana | |||||

| ʻO ka hiki i ka makasini mea hana | T | 16 | 16 | 24 | 24 |

| Ka manawa hoʻololi mea hana | s | 2.5 | 2.5 | 2.5 | 2.5 |

| Ka pololei o ka hoonoho ana (National standard) | |||||

| Ka pololei o ke kūlana (X/Y/Z) | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| Hoʻonohonoho hou i ka pololei (X/Y/Z) | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| ʻAʻOLE. | inoa | Brand |

| 1 | ʻōnaehana CNC | Seimens 808D SYSTEM |

| 2 | kaʻa nui | ʻO ka pahu holoʻokoʻa o Siemens me ka mīkini servo |

| 3 | X/Y/Z axis motor, hoʻokele | Seimens |

| 4 | pōʻalo | Hiwin a i ʻole PMI (Taiwan) |

| 5 | ʻO ka pahu pōʻeleʻele | NSK (Iapana) |

| 6 | Nā alakaʻi laina | Hiwin a i ʻole PMI (Taiwan) |

| 7 | ʻO ka motika spindle | POSA/ROYAL (Taiwan) |

| 8 | Mea hoʻololi wela | Taipin/Tongfei (Hoʻoikaika Hui) |

| 9 | Nā mea nui o ka ʻōnaehana lubrication | Proton (ʻoihana hui) |

| 10 | ʻO nā mea nui pūnaewele pneumatic | AirTAC (Taiwan) |

| 11 | Nā mea nui o ka ʻōnaehana uila | Schneider (Palani) |

| 12 | Pum wai | Kina |